Welcome to the enchanted world of vanilla alchemy, the adventure that guides us towards how vanilla is made. It begins with the beautiful petals of the vanilla orchid and culminates in the manufacture of a unique flavour. The term “vanilla alchemy” describes the delicate and tedious process by which this treasured flavour transforms from vanilla orchid flowers into the magnificent extracts that delight our culinary creations. Like that of an alchemist, changing basic materials into gold requires carefully maintaining and nurturing the vanilla orchid, hand-harvesting its valuable pods, and delicately extracting the essence within. Through this voyage, we will learn how vanilla is made.

Vanilla is one of the most adored and demanding flavours in the culinary world, thanks to its ageless and seductive smell. This fragrance, which is extracted from the blossoms of the vanilla orchid, has captivated the senses of culinary experts for generations. The flowery fragrance in the flower is converted into flavour for a wide range of meals, from sweet to savory. It perfectly blends into both traditional and modern dishes. Vanilla acts as a key element, enhancing and combining flavours with its own character, from vanilla ice cream to the flavors of pastries and confections. Vanilla is known for its international charm as it has widespread use in many culinary traditions.

The Vanilla Orchid: Flavour’s Origin

Its origins lead us to explore how vanilla is made. Starting from the vanilla orchid, the source of the exquisite vanilla flavour, which has its origins in tropical locations where heat and humidity reign, It is native to the regions of South and Central America, as well as the Caribbean, and the Totonacs of Mexico’s eastern coastline are believed to be the first to plant it. The delicate and fascinating plant thrives in areas like Madagascar, Tahiti, and Mexico. This variety of orchid requires an extensive framework, like a tree, for support, unlike the others growing in the air. The cultivation process begins with careful planting and meticulous nurturing.

The orchid blooms with gorgeous, fragrant flowers, but here’s the catch: these blossoms are only present for a short time and must be pollinated swiftly in order to turn into the vanilla pods we know and enjoy. This stage of the process frequently includes a delicate dance with nature, with human hands occasionally required to aid in pollination. Once pollinated, vanilla pods take their time ripening on the vine, eventually becoming the source of the famous vanilla flavour that finds its way into our favourite delights and desserts.

Read More:

- Is Mushroom Veg or Non Veg? – Let’s Know the Amazing Fact

- What is Black Wheat? Exploring Dynamic Black Wheat Benefits

Conditions Required for Optimal Vanilla Orchid Growth | How Vanilla is Made

- Warmth: Vanilla orchids prefer warm temperatures ranging from 21 to 35 degrees Celsius. It is essential for their growth and blossoming.

- Humidity: These orchids are native to humid tropical environments, so they require a relative humidity range of 80–90% to flourish.

- Filtered Sunlight: They need to have 60–80% shade to shield them from direct sunlight, especially during the warmest hours of the day.

- Support Structure: Requires a solid framework such as a trellis or pole to climb, develop, and produce pods.

- Watering: The soil should be kept regularly wet, and it benefits from sprinkling periodically to increase humidity levels.

- Nutrient-rich soil: soil that is slightly acidic to neutral in pH is preferred. During the growth season, a balanced orchid fertiliser can help plants meet their nutritional requirements.

Pollination Process Leading to Vanilla Bean

Vanilla orchid pollination is an important and intriguing part of vanilla bean cultivation, influencing both the amount and quality of the ultimate crop. Pollination is a fascinating part of the journey of how vanilla is made because vanilla orchids are self-sterile; they cannot pollinate their own blossoms. This unusual reproductive intricacy demands external assistance, either from human hands or, in their natural environments, specialised pollinators like bees and hummingbirds. As pollination commences, the membrane that separates male and female reproductive organs needs to be carefully raised or handled.

In areas where natural pollinators are sparse, human intervention is essential, necessitating the painstaking transmission of pollen with tools such as toothpicks. Pollination successfully converts the orchid bloom into the coveted green pod—the vanilla bean. This kickstarts the journey of how vanilla is made. Only pollinated blossoms grow into these valued pods to give better plumper, longer, and more aromatic beans, enhancing the overall quality of the final vanilla bean.

Harvesting Vanilla Beans: From Green Pods to Culinary Gold

Let’s look at how its harvesting takes place. Harvesting vanilla beans at their peak flavor is a real art that demands accuracy and patience. When the vanilla pods reach a certain degree of maturity, it indicates that they are prepared for harvest. This is the crucial process in deciding how vanilla is made.

| SNO. | PROCESS UNDERTAKEN | FUNCTIONS HANDLED |

| 1. | Harvesting | Pods exhibiting optimal size and colour (plump, dark green, and exuding a distinct aroma) are handpicked. |

| 2. | Curing | Harvested vanilla pods are typically blanched in hot water (halting enzymatic activity) |

| 3. | Sweating | Pods are wrapped in blankets or placed in airtight containers (which induce vanillin development) |

| 4. | Drying | Vanilla pods are laid out in the sun (day), then carefully wrapped and kept (night) for 3–4 weeks (concentration of flavour) |

| 5. | Resting | Left to rest in a cool and dark place (flavours mature and stabilize) |

How Vanilla Essence is Made: Unveiling the Fine Distinctions

We all would have come across vanilla essence and vanilla flavour in our own kitchen, packed in dark-colored small bottles which we use to make cakes, chocolates, sweets, put in rice items, etc. Have you ever wondered how vanilla essence is made or how vanilla flavour is made? These are created through a systematic procedure that concentrates vanilla beans into concentrated forms after the development of vanillin, the compound responsible for the characteristic vanilla flavour. The processes involved in extracting the flavours and smells from the beans to make vanilla essence are:

- Extraction: Cured vanilla beans are macerated in alcohol, often ethanol or a mixture of ethanol and water. This extracts the flavours and smells from the beans, resulting in a concentrated liquid essence.

- Filtration: The liquid is next filtered to eliminate any solid particles, yielding a clear and purified vanilla essence.

- Dilution: Vanilla essence is diluted with extra alcohol or water to get the appropriate strength and consistency. Due to this, the essence may be readily included in recipes, and the flavour strength can be precisely controlled.

- Bottling and Packaging: The finished vanilla essence is bottled and packaged for sale. Dark-coloured bottles are frequently used to protect the essence from light while retaining its flavour and scent.

Read More:

- Is Aloe vera farming profitable? 100% Genuine Fact Check

- How makhana is made | Latest Makhana farming in India

How Vanilla Flavour is Made: Way Towards Creation

From the high-quality vanilla essence, a concentrated form of vanilla derived from vanilla beans determines how vanilla flavour is made.

- Choosing Complementary Flavours: Selecting more natural flavours to compliment the vanilla essence, like caramel, chocolate, or other fragrant ingredients.

- Tailoring the sweetness: Sweeteners such as sugar or syrup can be used to adjust the sweetness level as required according to the intended use and taste preferences.

- Homogenizing and blending: In exact quantities, the vanilla essence is combined with chosen flavours, and sweeteners. Blend the mixture thoroughly to produce a uniform distribution of flavours and sweetness.

- Taste and Quality Assurance: Conduct taste tests to evaluate the flavour profile as well as quality control measures to maintain consistency and authenticity. This could involve sensory evaluations, taste assessments, and analytical testing to uphold established standards.

The final vanilla flavour is packed for delivery once the required flavour profile has been attained. The packaging guarantees that the flavour remains consistent and of high quality.

How Imitation Vanilla is Made: The Science Behind the Substitute

There are large differences between how vanilla is made and how imitations are made. The substitutes for real vanilla are often known as vanilla flavouring or vanillin, which is made by synthesizing vanillin, the primary flavour molecule responsible for the distinctive taste and scent of genuine vanilla. This is the way vanilla flavour is made at National Geographic, as the substitutes are readily available in the market. Let’s look into how imitation vanilla is made, and this will give a clear picture of how to distinguish it from the real ones.

The following are the basic procedures for making imitation vanilla:

- Sourcing of Raw Materials: Guaiacol, a chemical formed from lignin, a natural polymer found in wood, is frequently used as the major raw ingredient for imitation vanilla. Guaiacol is the beginning point for the production of vanillin.

- Vanillin Precursor Production: Various chemical procedures are used to turn guaiacol into a precursor component that may then be transformed into vanillin. This includes oxidation and condensation processes.

- Vanillin conversion: To produce vanillin, the precursor ingredient undergoes chemical changes such as oxidation or other processes. This is frequently accomplished by chemical synthesis, resulting in vanillin, a synthetic but chemically similar form of the component present in natural vanilla.

- Purification: The vanillin that has been synthesised is next purified to eliminate any impurities or by-products of the chemical processes. Purification ensures that the finished product fulfils the appropriate taste and odour criteria.

- Formulation and flavor enhancement: Purified vanillin is frequently mixed with others to generate a well-rounded and balanced flavour character. These extra ingredients may include coumarin, ethylvanillin, or other compounds that provide richness to the imitation vanilla flavour.

- Dilution and Standardization: Depending on the intended use, imitation vanilla may be diluted with water or alcohol and standardized to reach a constant strength. This phase gives you complete control over the flavour intensity.

The finished product is packed for sale in the form of liquid, powder, or as a component of other culinary products.

The National Geographic Perspective: Vanilla Flavor Across the Globe

The cultural significance of vanilla varies by place, and its different flavour characteristics contribute to the diversity of world cuisines. High-quality vanilla production is intimately linked to certain geographical locations noted for their favourable climatic and soil conditions that allow vanilla orchids to develop to their full potential.

Cultural Significance of Vanilla

| SNO. | LOCATION | FLAVOUR | CUISINE |

| 1. | Madagascar | Creamy and sweet | Desserts and savoury dishes |

| 2. | Mexico | Bold and spicy | Chocolate-based dishes and traditional Mexican desserts |

| 3. | Tahiti | Fruity and floral notes | Tropical desserts, ice creams and cocktails |

| 4. | Uganda | Bold and robust | White meats and seafood |

| 5. | Papua New Guinea | Strong, smoky and woody notes | Fish dishes, white meat |

The Culinary Journey: How Vanilla Ice Cream Is Made

The culinary journey with vanilla is never-ending, as it give rise to several elixirs One such magic is vanilla ice cream. Here’s how vanilla ice cream is made, which melts our senses. The ingredients required are:

- 2 cups heavy cream

- 1 cup whole milk

- ¾ cup granulated sugar

- A few drops (1-2) of pure vanilla extract

- Pinch of salt

Steps involved in preparation:

1. Making an Ice Cream Base:

Whisk together heavy cream, whole milk, granulated sugar, vanilla extract or vanilla bean paste, and a sprinkle of salt in a mixing bowl until the sugar is completely dissolved.

2. Heat the ingredients:

Place the ingredients in a saucepan over medium heat. Stir constantly until it reaches consuming (just before boiling) temperature.

3. Cool the mixture:

Allow the mixture to cool to room temperature. Refrigerate the mixture for several hours or overnight to allow the vanilla to permeate.

4. Churn in the Ice Cream Maker:

Pour the chilled liquid into an ice cream machine and churn it for 20–30 minutes or as much as required until it reaches a soft-serve consistency.

5. Freeze:

Place the churned ice cream in a container with a cover and freeze it at least for 4 hours, or until the mixture is firm.

Crafting the right kind of vanilla ice cream necessitates meticulous attention to detail and the use of premium components. These methods assure a delicious ice cream treat, from selecting the proper vanilla extract for an authentic and robust flavour to obtaining the ideal one.

Read More:

- 10 Beautiful Flowers We Eat As Vegetables For A Healthy Life

- 5 Top Tea Producing States in India: Alluring Tea Industry

Conclusion: The Endless Alchemy of Vanilla

The path from vanilla orchid blooms to delightful elixirs is a tedious procedure that flawlessly integrates art and science, converting the beautiful vanilla orchid blossoms into the cherished vanilla flavour. The objective is to capture the richness of vanilla and increase its variety in culinary applications through the extraction of essence or flavour formulation.

This journey has a global influence since vanilla is a key element in culinary arts and culture across the world. A fusion of art and science, where the complexities of cultivation and the precision of produce collide to produce the cherished vanilla flavour It’s warm, sweet, and somewhat flowery aromas may elevate a wide range of foods, from traditional sweets to new savory recipes. Vanilla demand transcends boundaries, with places such as Madagascar, Tahiti, and Mexico adding distinct flavour qualities to the worldwide culinary art. This olfactory voyage not only enriches the culinary arts world, but it also crosses cultural barriers, leaving an unforgettable impact on the global palette.

Latest Post

- Study Agriculture Abroad : A Complete Guide for USA

- July Issue (2024): Times of Agriculture Magazine

- Why Money Plant is called Money Plant ? Answer in 5 min

- How to grow Monstera from Cutting: 5-Step Detailed Guide

- Latest 10 Finest Terrace Garden Ideas to Transform Your Rooftops

- Top 10 Low Light Hanging Plants to make your Room Crunchy

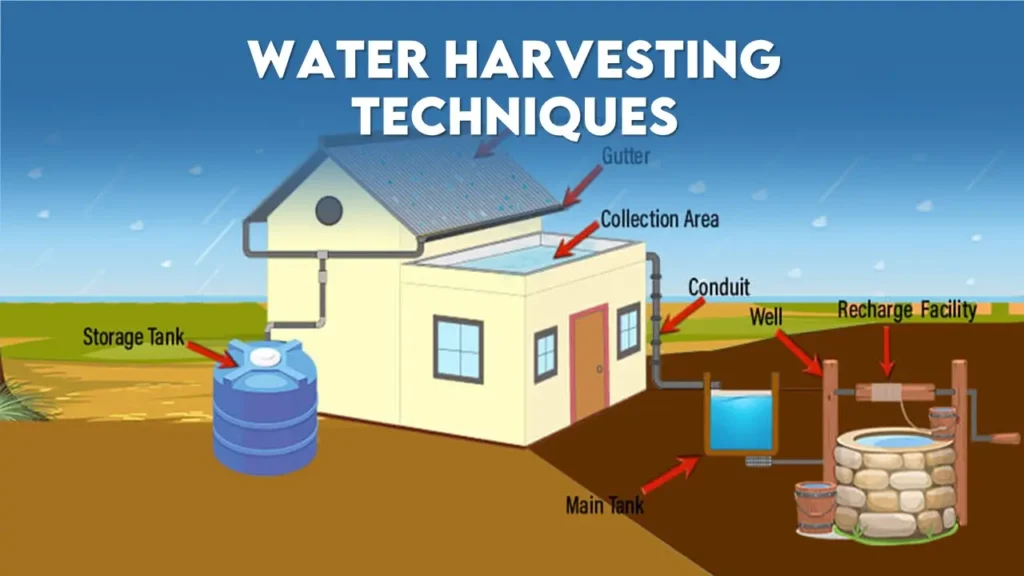

- Best Water Harvesting Techniques for a Sustainable Future

- Low Maintenance Indoor Plants for India: 15 Best plants for home gardening

- Top 23 Flowering Trees in India: Flower Tree for Home